Healthcare 3D Printing

3D Printing

Education Center

Learn More About Heathcare 3D Printing

We provide industry-leading surgical planning, implants, and instrumentation to help medical device manufacturers and healthcare providers accelerate innovation and transform healthcare

ProJet MJP 2500 Plus

Capable of printing in Ultra High Definition mode, the ProJet® MJP 2500 Plus makes it possible to print even smaller features, down to 300 microns or finer.

The ProJet MJP 2500 Plus offers additional capabilities, with a broader range of rigid materials available in clear to several opaque colors, as well as materials with properties that mimic engineering plastics, elastomers, and high-temperature resistance.

Applications include concept modeling, form and fit testing, functional prototyping, fluid flow analysis, rapid tooling, jigs and fixtures, and medical applications requiring USP Class VI and/or ISO 10993 certification for biocompatibility.

DLP (Digital Light Processing)

DLP machines use a projected light source to cure the entire layer at once. Figure 4® delivers ultra-fast additive manufacturing technology with systems that offer the expandable capacity to meet your present and future needs. With access to a range of innovative materials, Figure 4 enables tool-less alternatives to traditional injection molding or urethane casting processes with direct digital production of precision plastic parts and ultra-fast same-day rapid prototyping.

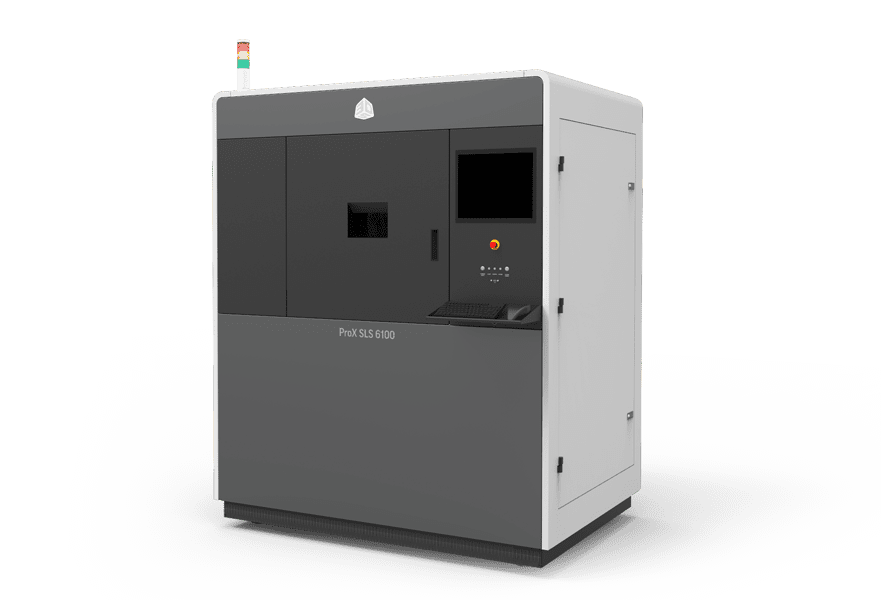

SLS 3D Printer

Expand your manufacturing capabilities with production-grade nylon materials to produce tough, functional complex parts with excellent surface finish, resolution, accuracy, repeatability and low total cost of operations. SLS printers print in thermoplastic materials designed to offer full capabilities and isotropic properties, from rigid to elastomeric, high elongation, high impact strength, and high-temperature resistance.

SLA 3D Printers

3D Systems—the inventor of Stereolithography (SLA) and the only SLA manufacturer offering the total solution with integrated hardware, software and materials fine-tuned to achieve renowned SLA parts quality—brings you legendary precision, repeatability and reliability in SLA 3D printers. SLA printers work with a wide range of materials, with a range of sizes and price points, which are designed for prototyping, end-use part production, casting patterns, molds, tooling, fixtures and medical models.

SLA 3D Printers

3D Systems—the inventor of Stereolithography (SLA) and the only SLA manufacturer offering the total solution with integrated hardware, software and materials fine-tuned to achieve renowned SLA parts quality—brings you legendary precision, repeatability and reliability in SLA 3D printers. SLA printers work with a wide range of materials, with a range of sizes and price points, which are designed for prototyping, end-use part production, casting patterns, molds, tooling, fixtures and medical models.

Metal 3D Printing

Design, test and produce metal parts with 3D printing that are simply not possible with standard manufacturing. Create lightweight, high-strength structures and deliver new capabilities.

EXT 220 MED

The EXT 220 MED with its filament-based extrusion technology enables printing of implants and instruments using high performance polymers, including PEEK and Radel® PPSU.

THE FIRST 3D PRINTING PLATFORM SPECIFICALLY DESIGNED FOR MEDICAL DEVICE PRODUCTION

Brainstorm Your Solution

We help you find clarity in the crowded world of 3D printing and software. Start with Nota3d.

Book Appointment

Our favorite thing is to learn about you and your specific goals when it comes to 3D technology. We have various solutions and will help you find the right fit, even if it isn’t from us.

Contact Us

Call us

414-207-4404