NextDent 300

3D Printed Multi-Material Jetted Dentures

Superior quality, fast, highly aesthetic monolithic dentures production

The NextDent 300 produces a one-piece, removable dental protheses with custom-blended teeth shades. This solution delivers an unparalleled combination of outstanding aesthetics and distinctive fracture resistance. The printer blends polymers on-demand to deliver accurate shade matching. Save time and take cost out of your manufacturing process by going from CAD data to a multi-material single part denture without the need for any additional assembly.

Superior Quality

Prints highly accurate denture bases and teeth with superior strength and realistic appearance in 12-14 hours of total labor time without sacrificing quality.

NextDent Materials

NextDent biocompatible materials are engineered for lifelike aesthetics, long-term durability, and patient comfort.

Easy to Use

Simple user interface guides you through the end-to-end printing process to maximize uptime, efficiency and productivity.

Plug and Play

Easy to install ecosystem that is up and running within an hour from delivery. Your lab can start printing with access to a power outlet.

NextDent 300 MultiJet 3D Printer

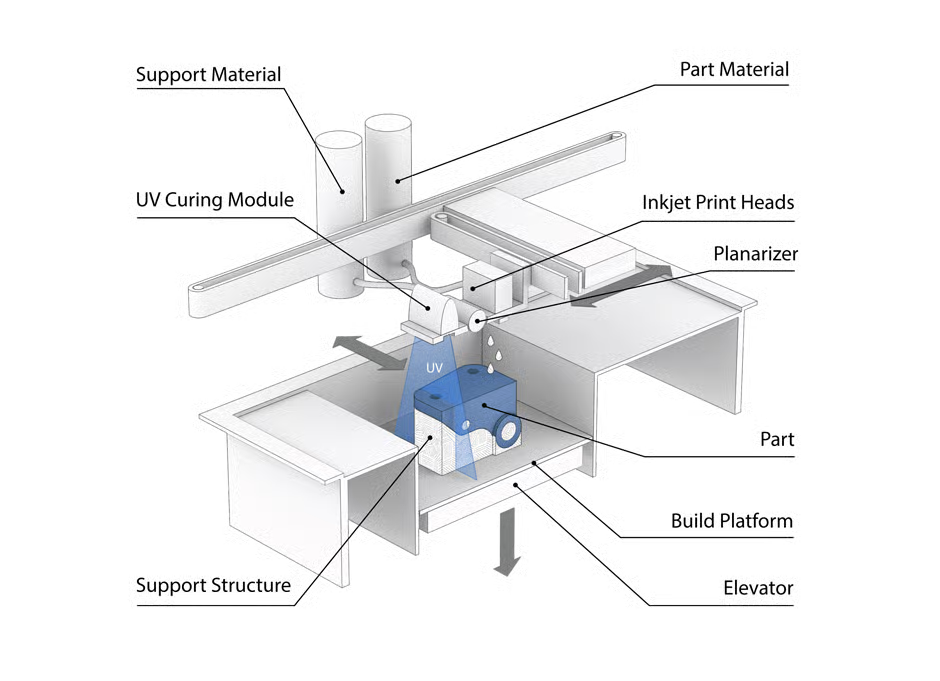

MJP jetted acrylate printer with multi-material capability

- Blended polymers on demand for custom shade matching

- Best-in-class denture mechanical properties

- Easy, hands-free support removal

Materials

- NextDent Jet Base LT

- NextDent Jet Teeth White

- NextDent Jet Teeth Yellow

- Wax support material

Easy and Clean Material Handling

Clean, smart-cartridge design keeps users safe from uncured plastics. Two cartridges for each material enables replenishment while the printer is in operation.

Integrated rotating touch screen with contextual help guides makes everyone an expert.

The control panel for the NextDent 300 makes keeping track of important details fast and easy. The fully redesigned user interface in a glance provides the printer status, estimated finishing time, material levels and print history. Contextual help guides and instructs you through the entire printing process including loading materials, maintenance or accessing finished dentures.

MJP for Jetted Dentures

MJP technology revolutionizes digital dentistry by enabling dental labs to produce ultra-precise, monolithic dentures with exceptional speed, accuracy, and efficiency. Unlike traditional fabrication methods, MJP prints high-resolution, biocompatible materials in a single seamless build, ensuring a superior fit, natural aesthetics, and long-term durability. With its high-speed production capabilities, minimal post-processing, and reduced material waste, MJP streamlines workflows, lowers costs, and enhances scalability for labs of all sizes.