SLS 3D Printing Technology

Production-Grade SLS Workflow Solution

The SLS 380 is a high throughput SLS additive manufacturing solution with unprecedented levels of throughput, consistency, performance, and yield. Optimized for those who want to take the next step in integrating additive manufacturing into their factory-floor ecosystem, 3D Systems’ SLS 380 and its complementary software, material handling, and post-processing solutions answer the demand for cost-effective batch production parts.

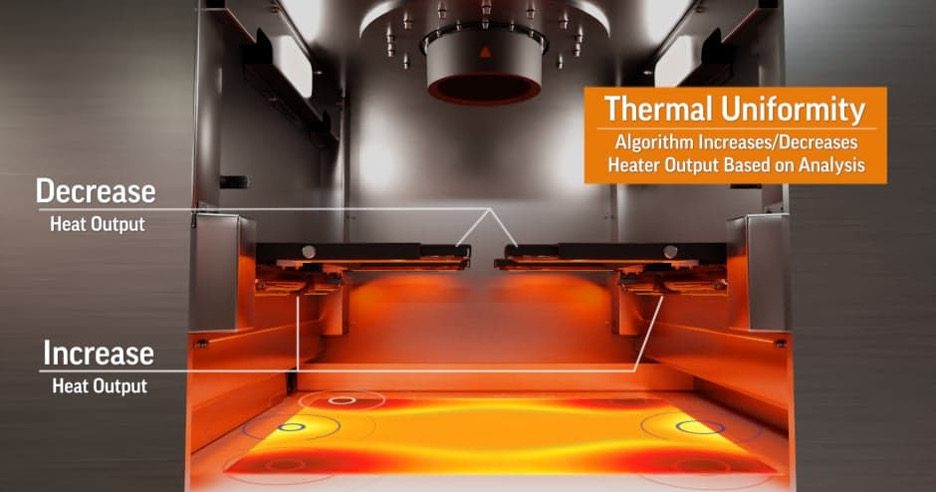

100,000 Thermal Data Samples Per Second

The algorithm manages eight separately calibrated heaters, together with an integrated high-resolution IR camera that captures over 100,000 thermal data samples from within the build chamber per second. This data, together with the IR sensor, maintains temperature stasis for every part build-layer, for the duration of the build process. With a more consistent thermal uniformity across the build process, manufacturers can now deliver more dimensionally stable parts with better mechanical performance, higher repeatability, and greater yields – all with fewer human interventions and lower overall operating costs.