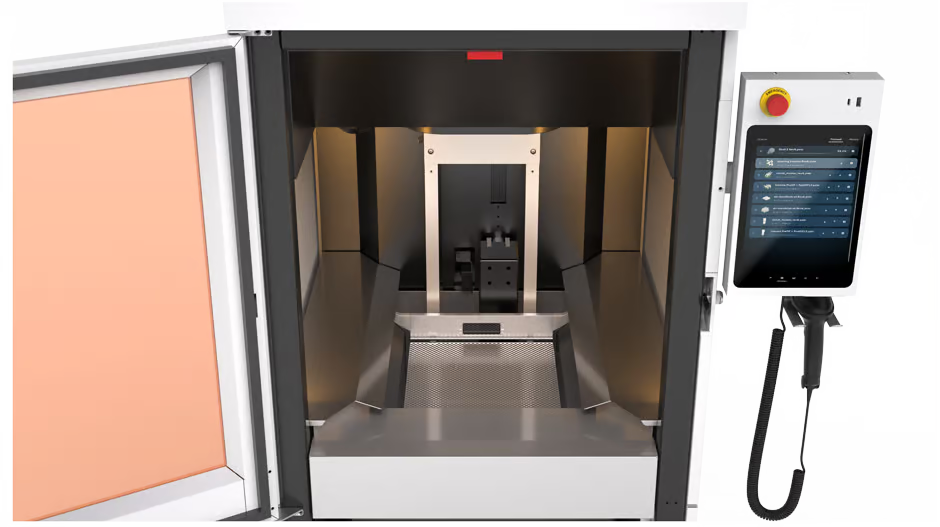

PSLA 270

Projection-based SLA System

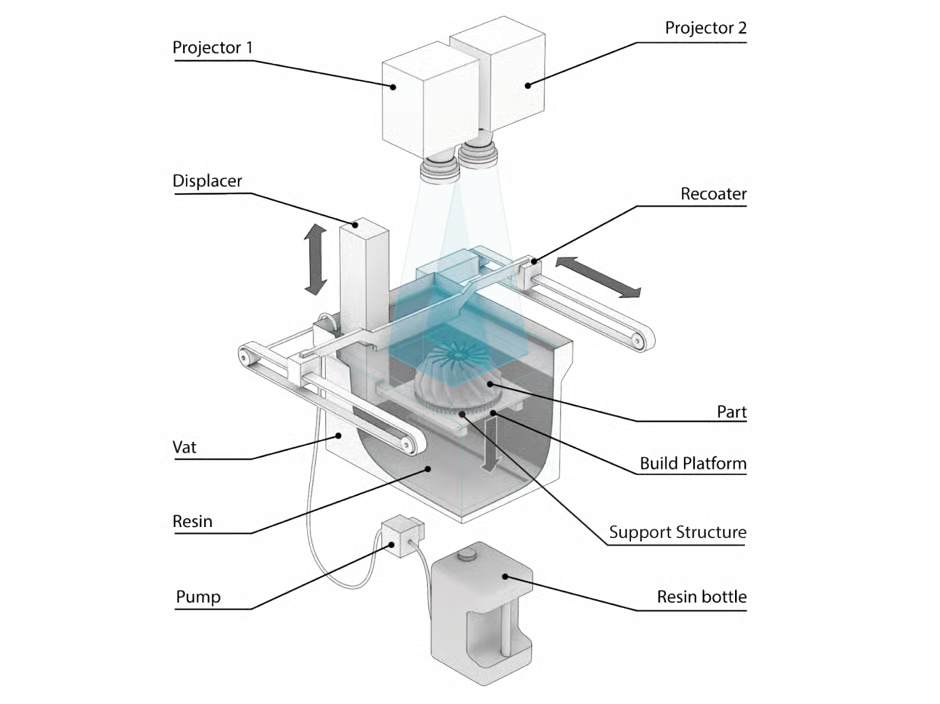

The PSLA 270 architecture merges the best of both worlds: the pixel productivity of projection-based technology and the buoyant, non-contact precision of SLA. Its dual high-resolution projectors deliver unmatched pixel efficiency, far surpassing traditional laser systems.

Fast

Dual HD projector-based SLA offers up to 5x faster curing layer times compared to laser-based technology.

Precise

Our high power 7 watt projectors deliver first article success at 90µm pixel resolution, with exceptional print quality and repeatability.

Versatile

Compact size with a large build volume capacity. The perfect tool for service bureau and production applications.

Easy to Use

Simple user interface guides you through the end-to-end printing process to maximize uptime and productivity.

Easy to Install

Passes through a standard doorway and can be set up in a few hours. You only need a standard power outlet to start.

Production-grade Resins

The PSLA 270 is designed to operate with the Figure 4 range of engineering and production-grade resins delivering printed parts with an injection-molded like quality and best-in-class smoothness.

Choose from our ever-expanding range of rigid, tough, durable with thermoplastic-like behaviors, castable, heat-resistant, and biocompatible capable materials in a range of colors and translucencies. Printed parts exhibit long-term UV and humidity stable mechanical properties; up to 8 years for indoor use and up to 1.5 years for outdoor exposure per ASTM D4329 and ASTM G194 methods.

Part Quality

PSLA 270 produces exceptional part quality and accuracy, a direct result of our trade secret pixel blending methods combined with precision projectors and innovative hardware configuration.

In order to guarantee best-in-class part quality, all our materials, print processes, image processing software, and printer hardware, are developed from +15yrs of 3D Systems’ print process experience with pixels, ensuring seamless integration.

3D Systems’ image processing software automatically adjusts the pixel edges with gray scaling techniques. This results in high-quality production-grade plastic parts with best-in-class surface quality.